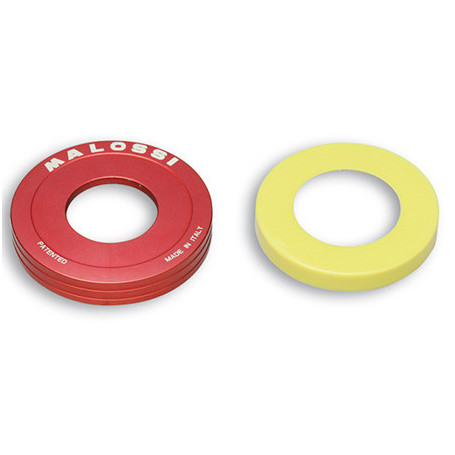

Antifriction fifth wheel for variator contrast spring

A secret from Malossi racing department

Light, perfect: a technology extract in its simplicity; design and formula of the materials are registered.

Abstract from of Malossi Engineering R& D department archives

CVT Transmission systems.

Chapter : contrast spring.

Goal

Pull down vibrations and to make the system operation stable at any rpm and temperature.

Design path

We have considered both on theoretical and practical basis all the existing fifth wheel systems: balls, rollers and radial sliding fifth wheels of metal type. All the tests gave unsatisfactory results. We have made prototypes with alternative systems, metallic type, without any positive results. Only after exhausting laboratory and racetrack tests we have eventually come to Torsion Controller design.

Thesis

The above-mentioned component solves the following problems.

During gear curve range the bushing of the movable pulley (torque drive) slides into the driven pulley in axial way along fixed pulley hub, making a small rotation which gives a torsion to the contrast spring. Sometimes the spring loses its position while frictioning on the shoe-holder plate, metal against

metal; some others, the spring remains stuck in its position causing some accidentally different contrast forces.

Second problem: centrifugal forces caused at high rpm affect the spring which consequently buckled and starts to veer as to create big vibrations, very annoying for the driver as well as dangerous for the engine and, above all, making unsteady the gear curve.

Result

We approved the project with great success after strict tests at R & D department and on racetrack on all examined scooter models.

Compatible with: - Yamaha: T-MAX 500 04-07_S, T-MAX 500 08-11_S, T-Max 530 12-_S

Chapter : contrast spring.

Goal

Pull down vibrations and to make the system operation stable at any rpm and temperature.

Design path

We have considered both on theoretical and practical basis all the existing fifth wheel systems: balls, rollers and radial sliding fifth wheels of metal type. All the tests gave unsatisfactory results. We have made prototypes with alternative systems, metallic type, without any positive results. Only after exhausting laboratory and racetrack tests we have eventually come to Torsion Controller design.

Thesis

The above-mentioned component solves the following problems.

During gear curve range the bushing of the movable pulley (torque drive) slides into the driven pulley in axial way along fixed pulley hub, making a small rotation which gives a torsion to the contrast spring. Sometimes the spring loses its position while frictioning on the shoe-holder plate, metal against

metal; some others, the spring remains stuck in its position causing some accidentally different contrast forces.

Second problem: centrifugal forces caused at high rpm affect the spring which consequently buckled and starts to veer as to create big vibrations, very annoying for the driver as well as dangerous for the engine and, above all, making unsteady the gear curve.

Result

We approved the project with great success after strict tests at R & D department and on racetrack on all examined scooter models.

Compatible with: - Yamaha: T-MAX 500 04-07_S, T-MAX 500 08-11_S, T-Max 530 12-_S

Compatibility

- Kymco

- AK 550_S

- Yamaha

- TMAX 500 04-07_S

TMAX 500 08-11_S

TMAX 530 17-_S

TMax 530 12-16_S

The prices shown are valid only for online purchases and not in-store